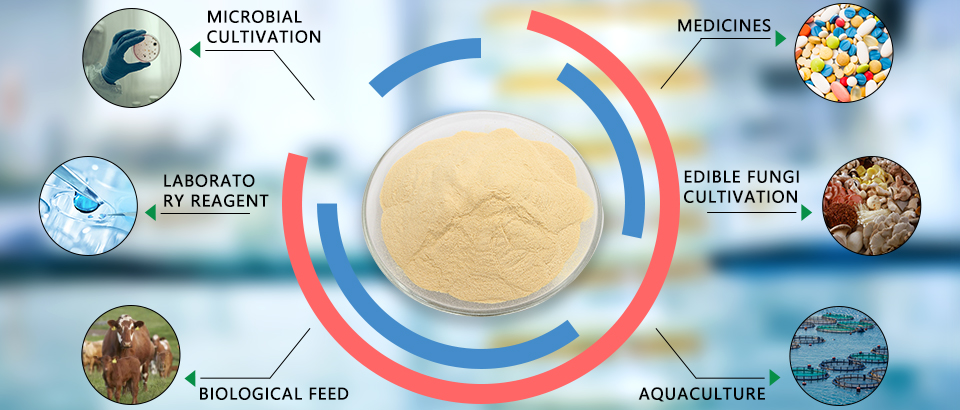

Fermentation

Application of Microbial fermentation

1. Biopharmaceutics

Microbial pharmaceutical technology is the most important component of industrial microbial technology. The usage of microbial medicine began with what is known as antibiotics. In recent years, due to the development of essential life science and the application of various new biotechnology, the reports on bioactive substances produced by microorganisms besides anti-infection and anti-tumor substances are increasing, e.g. specific enzyme inhibitors, immunomodulators, receptor antagonists and antioxidants etc., whose activities have exceeded the limits of inhibiting the life activity of some microorganisms. However, these substances are all secondary metabolites of microorganisms, which have common characteristics in the mechanism of biosynthesis, screening study procedures and production process, etc., and these secondary metabolites produced by microorganisms with physiological activities (or pharmacological activities) are collectively called the microbial pharmaceutical. Accordingly, It includes traditional antibiotics have the effact of anti-microbial infection and anti-tumor as well as specific enzyme inhibitors, immunomodulator, receptor antagonist, antioxidants, and so on. And all microorganisms’ growth depends on the microbial culture medium.

2. Amino Acid Fermentation

Nearly 20 amino acids can be produced by microbial fermentation technology. However, microbial cells have an automatic metabolic regulation system that prevents excessive accumulation of amino acids. If a large number of amino acids are accumulated in the culture medium, it is necessary to remove or break through the metabolic regulation mechanism of microorganisms. Amino acid fermentation is an important achievement in controlling this mechanism. The isolation and screening of wild strains from nature and the control of their cell membrane permeability are conducive to the secretion of large amounts of L-glutamic acid, which is also an important way to obtain excellent strains of L-glutamic acid fermentation microorganisms. Secondly, through artificial mutation of L-glutamic acid producing strains, various amino acid-producing mutant strains are bred, which is an effective method to obtain excellent strains of other amino acid-producing microorganisms.

3. Biological Feed/ Fertilizer

The concept of biological feed was put forward in the last decade, and the comprehension of its definition and connotation is changing with the development of science and practice. Broadly, biological feed shall include all feed or raw materials except the synthetic additives. Worldwide biological feed products have developed dozens of varieties to have become a major industry, mainly including the feed enzyme, forage amino acid and vitamin, probiotics (directly feeding microbes), forage oligosaccharides, natural plant extract, bioactive oligopeptides, feed biological pigment, new feed protein, biological medicine feed additive, etc. In China,we paid more attention to produce forage enzyme, probiotics, bioactive oligopeptides, oligosaccharides, etc. in the research and production process, which are inseparable from microbial culture medium.

A multitude of applications of chemical fertilizers and pesticides have both advantages and disadvantages for human beings. In order to eliminate the disadvantages, scientists have proposed ecological agriculture, which gradually realizes to use fewer or no chemical fertilizers and pesticides in farmland, and organic biological fertilizers and microbial methods to control diseases and insect pests. Existing biological fertilizers are based on organic matter culture medium and then mixed with inoculum and inorganic fertilizers. In order to improve this general and traditional situation extensively, biological fertilizers go far beyond existing concepts. It will provide both crop nutrients and soil improvement; meanwhile, the soil should be disinfected, that is, biological (mainly microorganisms) decomposition and elimination of pesticides (pesticides and fungicides), herbicides and pollutants from petrochemicals in the soil, as well as the remediation of soil.

4. Aquaculture

Culture medium is prominent in aquaculture industry. It has been studied to use microorganisms as a nutrient source in the aquaculture industry for a long time. Modern fermentation technology and microbiology make it possible to produce a multitude of microbial feed. Feed yeast is rich in many trace elements and vitamins needed by aquatic animals and has become an important additive in artificial proportion bait such as fish and shrimp. Experts replaced some fish meal with feed yeast in the process of mixing shrimp bait, which improved the yield and survival rate of shrimp compared with traditional feed. Shellfish culture is a state of progressive development in China, but does not fully use the single-celled algae feed in the process of breeding. Farms usually replaced the algae feed with egg yolk that although met the nutritional needs of the growth of farmed animals to some extent but would make some damages to the quality of breeding water to form the consequences of breeding is not ideal. Microorganisms cause many diseases, bacteria and virous do so. In addition to maintaining good water quality and using antibiotics, vaccination is also an effective way to prevent and treat bacterial and viral diseases. In practical aquaculture, vibrio vaccine has a very good effect on prevention and treatment of various fish diseases. Many people are trying to use microbes to boost the immunity of invertebrates. Abalone were inoculated and immunized by oral and injectable attenuated vaccine. The survival rate of the immunized abalone was increased more than 50 percent. Those lead us to believe that microorganisms grown through culture medium are very effective in preventing disease occurrence in large-scale aquaculture.

5. Environmental Protection

With the development of industry, the composition of sewage is becoming more and more complex. Some refractory organic substances and toxic substances need to be treated by microbial technology. Sewage has the conditions for the growth and reproduction of microorganisms which can get nutrients from the sewage to degrade and utilize the harmful substances and purify the sewage. Biological treatment of wastewater is a treatment method that uses the life activities of microorganisms to degrade organic pollutants in the wastewater in dissolved or colloidal state to purify the wastewater. The biological wastewater treatment technology is favored by people for its obvious advantages, such as low consumption, high efficiency, low cost, convenient and reliable operation and management, and no secondary pollution etc.

6. Edible Fungus Culture

The raw material of culture medium of Hongrun Baoshun is applied in the production of liquid species of edible mushroom by biological fermentation engineering to instead of the traditional simple solid seed production. It uses the principle of biological fermentation to provide the optimal nutrient, pH, temperature, oxygen supply for the growth of mycelium, which can grow and expand rapidly, and reach a certain number of mycelium in a short time to complete a fermentation cycle.

Customer can use the high quality and stable nitrogen source of Hongrun Baoshun, the best combination of peptone Y001C, yeast extract Y017C, defatted soybean extract Y030, and add the supplementary carbon source in the biological fermentation tank, to produce the liquid form edible fungus by submerged cultivation (liquid fermentation) technology.

The advantages of cultivated edible fungus:

1) Low cost;

2)Sufficient nitrogen source in short time;

3) Germination after 6 hours, hyphae covered the inoculation surface within 24 hours;

4) Fast growth: the fungus incubation time is 1/2 shorter than that of solid;

5) High purity: good dissolution of raw materials, no precipitated impurities, to make the strain purity high and vitality strong;

6) Less pollution: the germination rate of bacteria is fast to avoid the infection of heterozygous bacteria;

7) Short planting time: fast effect and high yield.

7. Enzyme Preparation

All kinds of enzymes are produced from microorganisms. Almost all enzymes in animals and plants can be obtained from microorganisms, and the most suitable strains can be obtained through isolation and screening. The microorganisms propagate fast, the growth cycle is short, the culture is simple, and the enzyme yield can be increased by controlling the culture conditions. Using fermentation method to produce enzymes has greater advantages than directly extracting enzymes from biological materials, such as production of bacillus subtilis, aspergillus niger, aspergillus oryzae and brewer yeast, etc.

The advantages of enzyme preparation produced by the special fermentation medium of enzyme preparation provided by Hongrun Baoshun: 1)The characteristics of the strain are stable; 2) High enzyme production capacity; 3) The capacity spore production is stable. 4) Not interfere with production or influence of the by-products of product(e.g. colloids, pigments, etc.); 5) The most important thing is the low price of raw materials, which greatly reduces the cost of enterprises.

8. Other Fields